Current Anodizing Processes

Sulfuric Acid Is The Preferred Method

Sulfuric Acid: The predominant anodizing process today. Coatings 0.1-1.0 mil thick formed in a 15 pct. solution, 12asf, 18-24 volts, 70F for 10-60 min. This coating is usually organically dyed or colored with deposited metals (two-step). Offers a wide array of applications. Most anodizers use this method, although other acids are available for specialty purposes.

Organic acids: These integral one-step processes employ 90-100 g/liter solutions of organic acids, containing a small amount of sulfuric acid (for increased conductivity). Operating conditions: 70-80F, 24asf, voltage up to 75; produces amber, bronze and black coatings. The resulting oxide coating is light-fast and weather resistant.

Six Anodizing Processes

Your Title Goes Here

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

Surface Coating

Working method

Working method

- Pretreatment

- Grounding (Chromatizing)

- Color Coating

- Curing of lacquer coat

Structure

- Grip coat ca. 1µm of Al oxide hydrates. Al-Cr phosphates

- Lacquer coat 30-80µm organ. polymers

- Color pigments distributed in lacquer coat

Shades

- Unlimited, including white; various degrees of gloss

Appearance of surface

- Metallic character of the aluminum lost, pigments cover underlying surface

Overall resistance

- Good, depending on binder type and pigment quality; chalking observable in most cases

Chemical stress

- Very good resistance to alkaline construction materials and corrosion influences

- May show chalking after a few years.

Mechanical stress

- Less resistant than anodized aluminum, flaking of lacquer coat possible

Color repairs

- Possible without dismantling, but with limitations;

- Shade/gloss is a problem

- Adhesion of repair lacquer may vary

Main applications

- Buildings with a normal to high representative character

Integral Coloring

Working method

Working method

- Pretreatment

- Anodizing (special alloy + organic acid)

- Sealing*

Structure

- Coloring matter distributed in hard Al oxide, inseparably bound to the aluminum; anodic film thickness 15-40µm

Shades

- Brown, bronze, gray, slate; no special colors; no white

Appearance of surface

- Metallic character of the aluminum retained

Overall resistance

- Outstanding, virtually unlimited durability, no chalking

Chemical stress

- Sensitive to alkaline construction materials

Mechanical stress

- Extremely resistant; no flaking

- These coats are considerably harder than surface coatings

Color repairs

- Impossible without dismantling (but alien retouching possible on the building)

Main applications

- Buildings with a highly representative character

Organic Dyeing

Working method

Working method

- Pretreatment

- Anodizing (no special alloy)

- Dyeing (with highly-fast organic dyes, without current)

- Sealing*

Structure

- Coloring matter (org. dye) in most cases incorporated throughout the coating, which is inseparably bound to the aluminum; minimum anodic film thickness 20µm

Shades

- Spectral colors; deep yellow, d. red, d. blue, d. turquoise, d. black; no brown, bronze or gray tones

Appearance of surface

- Metallic character of the aluminum retained; high brilliance

Overall resistance

- Very good

Chemical stress

- Sensitive to alkaline construction materials

Mechanical stress

- Like normal electrolytic dyeings; no flaking

- These coats are considerably harder than surface coatings

Color repairs

- Impossible without dismantling (but alien retouching possible on the building)

Main applications

- Buildings with a highly representative character and a distinctive colorful appearance

Inorganic Dyeing

Working method

Working method

- Pretreatment

- Anodizing (no special alloy)

- Dyeing (with highly-fast, inorganic dye salts, without current 1- or 2- bath)

- Sealing*

Structure

- Coloring matter (heavy metal oxide hydrates; Fe, Co, Mn) incorporated in outer region of coating; minimum anodic film thickness 20µm

Shades

- Pale to dark bronze and gold tones, muted

Appearance of surface

- Metallic character retained; anodic film somewhat duller, especially with gold tones

Overall resistance

- Very good

Chemical stress

- Sensitive to alkaline construction materials

Mechanical stress

- Practically as with absorptive dyeings; no flaking

- These coats are considerably harder than surface coatings

Color repairs

- Impossible without dismantling (but alien retouching possible on the building)

Main applications

- Buildings with high requirements as to appearance (metallic character)

Electrolytic Coloring

Working method

Working method

- Pretreatment

- Anodizing (no special alloy)

- Dyeing with metal salts and A.C.

- Sealing* or

- Coating with colorless lacquer, then curing

Structure

- Coloring matter at base of pores consists of metals in highly dispersed form inseparably bound to the aluminum; minimum anodic coat thickness 20µm

Shades

- Brown, bronze, gray, slate, black, pink, burgundy, no spectral colors, no white

Appearance of surface

- Metallic character of the aluminum retained

Overall resistance

- Outstanding, no chalking

Chemical stress

- Sensitive to alkaline construction materials

Mechanical stress

- Slightly less hard than color-anodized coats; no flaking

- These coats are considerably harder than surface coatings

Color repairs

- Impossible without dismantling (but alien retouching possible on the building)

Main applications

- Building with high requirements as to appearance (metallic character)

Electrolytic Coloring Combined With Organic Dyeing

Working method

Working method

- Pretreatment

- Anodizing (no special alloy)

- Dyeing with highly-fast organic or inorganic dyes

- Sealing* (Nt)

Structure

- One coloring matter at base of pores, the other incorporated in the coating; min. anodic coat thickness 20µm

Shades

- Virtually unlimited, muted shades, no white

Appearance of surface

- Metallic character and surface appearance of the aluminum retained

Overall resistance

- Outstanding, no chalking

Chemical stress

- Sensitive to alkaline construction materials

Mechanical stress

- Like normal electrolytic dyeings; no flaking

- These coats are considerably harder than surface coatings

Color repairs

- Impossible without dismantling (but alien retouching possible on the building)

Main applications

- Buildings with high requirements as to appearance (metallic character)

*Sealing = Closing the pores

The processes used and the results obtained for six anodizing color systems are detailed below.

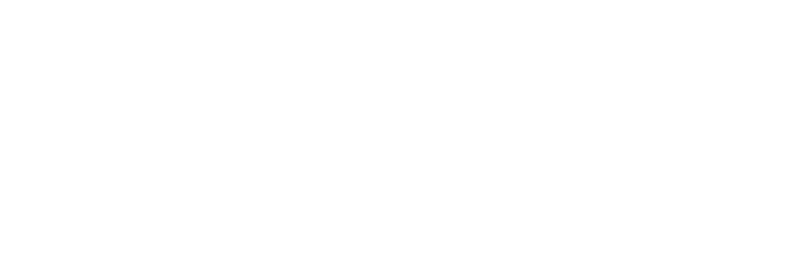

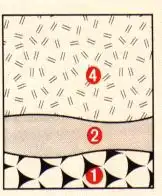

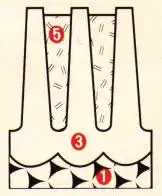

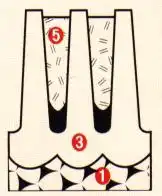

Use the following number key for the illustrations:

1 – Aluminum metal

2 – Chromate coating (as grip for lacquers)

3 – Aluminum oxide coating (as color anchor in anodizing process)

4 – Lacquer coating

5 – Coloring matter